The share of variable renewable energy, wind and solar, is strongly increasing and is expected to become the main source of electricity production in Europe by 2050.

Thermal power plants are facing challenges in the changing energy system and should be operated flexibly. These changes will be challenging for CHP-systems, which have been the backbone of the district heating in many countries of North-Europe. The FLEXCHX concept offers new business possibilities in combining fuel and heat production and by presenting a hybrid production concept which can integrate the use of biomass and solar or wind energy.

Main features of the process

FLEXCHX-process is a flexible and integrated hybrid process that combines electrolysis of water with gasification of biomass and catalytic liquefaction. This process produces heat, power, and an intermediate energy carrier, Fischer Tropsch (FT) wax, which can be refined to transportation fuels using existing oil refining equipment. FLEXCHX plants can be integrated with various combined heat and power production systems, both industrial CHPs and communal district heating units.

In the summer season, renewable fuels are produced from biomass and hydrogen; the hydrogen is produced from water via electrolysis that is driven by low-cost excess electricity from the grid. During the dark, winter season, the plant is operated with just biomass in order to maximize the production of much-needed heat, electricity and FT wax. Most of the invested plant components are in full use throughout the year - only the electrolysis unit is operated seasonally.

Validation of the key enabling technologies

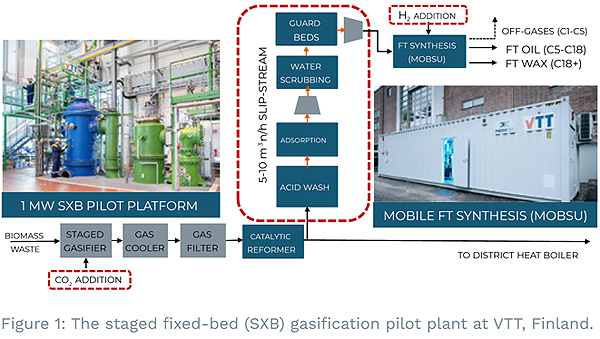

The main focus of the FLEXCHX project is on the development of flexible gasification, robust gas cleaning and compact synthesis technologies, which are developed at the 0.5 MW, pressurized, staged fixed-bed gasification pilot plant (SXB-Pilot) located at VTT’s piloting Centre Bioruukki, Finland (Fig.1). The gasifier was equipped with a special hot filter unit followed by a catalytic reformer, where tars and hydrocarbon gases are converted to H2 and CO. A slip-stream of the reformed gas was further purified in the novel ultracleaning process before leading the syngas into the FT unit.

The FLEXCHX project is currently in its third year and all critical experimental activities have been successfully completed. The SXBpilot plant was operated with various residues of forestry and agriculture for ca. 350 hours and all novel enabling technologies of the FLEXCHX project were developed and successfully tested. Consequently, the entire process chain from biomass gasification up to FT liquids production has been validated to TRL5. Biomass residues were converted to FT-hydrocarbons, which can be further refined to renewable transport fuels. Currently, the technical, economic and environmental feasibility studies are on-going to support the experimental development and plans for follow-on demonstration.

The new technologies of the project are expected to reach demonstration phase in around 2022 - 2023. Potential production sites are assessed together with the industrial partners especially in Lithuania and Finland, where biomass-based district heating plays an important role.

The The FLEXCHX is a 3-year (2018-2021) project funded by EU’s Horizon 2020 research and innovation programme under grant agreement No 763919.

The consortium comprises ten partners from four countries; VTT (Finland), Lithuanian Energy Institute (Lithuania), DLR (Germany), Enerstena (Lithuania), Johnson Matthey (UK), Neste Engineering Solutions (Finland), Kauno Energija (Lithuania), Helen (Finland), INERATEC (Germany) and Grönmark (Finland). The project is coordinated by VTT, Finland.

More information:

Website: http://www.flexchx.eu