The need for clean energy sources has led to a great development of wind power during last decades. Despite significant development and deployment achievements, offshore wind energy costs remain high compared to conventional forms of energy. Even with these signifi cant achievements the sector has made, there has been limited open-sea experience, which is essential in order to fully understand the challenges in device performance, survivability and reliability prior to market take-up. Scaling-up offshore renewables technologies will be crucial for the decarbonisation of the world’s energy system, in which, offshore wind has emerged as one of the most dynamic technologies.

In this context, Saitec started to work in 2013 on the idea of a new model of floating platform for wind turbines adapted to depths between 30m and beyond, and therefore, suitable for the requirements of new wind farms far from the coastline.

SATH Technology, Swinging Around Twin Hull, is an innovative and competitive concrete floating concept for offshore wind turbines suitable for shallow and deep waters (35m depth, onwards). Represents a disruptive change over current floating solutions due to the use of different construction materials (concrete instead steel), the Single Point Mooring configuration and the versatility of the design that makes it adaptable to very different water depths. Thanks to these characteristics, it will allow a reduction in LCoE not only over the current floating technology but also over the fixed bottom offshore wind solutions.

SATH Technology, Swinging Around Twin Hull, is an innovative and competitive concrete floating concept for offshore wind turbines suitable for shallow and deep waters (35m depth, onwards). Represents a disruptive change over current floating solutions due to the use of different construction materials (concrete instead steel), the Single Point Mooring configuration and the versatility of the design that makes it adaptable to very different water depths. Thanks to these characteristics, it will allow a reduction in LCoE not only over the current floating technology but also over the fixed bottom offshore wind solutions.

SATH floating platform key elements are: the use of concrete, the geometry of the floats, the arrangement of the structure and the mooring system, that presents the following significant competitive improvements compared to existing solutions in the market:

- The use of concrete instead of steel to reduce the construction, operation and maintenance costs as well as to extend its operational lifetime.

- The construction and assembly are made entirely onshore which reduces both investment costs and potential risks (e. g. labour, HSE, and weather windows), finally towing the assembly floating to site.

- Platform draught is reduced (draught <10 meters), which makes it suitable for both shallow and deep waters.

- It provides a Plug & Play solution, with easy connection process, so the platform can be easily installed or disconnected and taken ashore for major part repairs.

- It includes a single point mooring system, which allows the platform to rotate like a weather vane facing the wind. This helps the yaw control system of the wind turbine and reduces the stresses on the mooring lines.

Saitec Offshore Technologies (SOT) has the ambition to establish itself as a player in the wind energy sector, as developer and provider of an IPprotected technology, and therefore, will benefit significantly benefit from this project. SOT expects to play the role of an engineering company, selling the right to use its design based on royalties and with a fee depending on the depth.

SATH 1:35 scaled prototype versions were tested and validated in the Hydraulic Institute of Cantabria and in IFREMER (France) with the assistance of an international certification company (DNV) in order to explore the combined effects of wind, waves and currents.

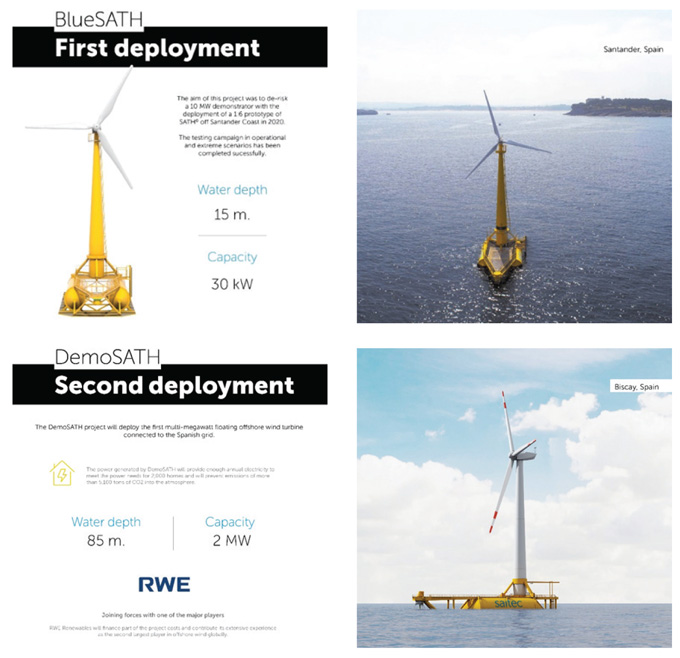

In December 2018, Saitec Offshore received the notification from the European Commission confirming the award of the grant for BlueSATH project (849307), inside the H2020 call's SME Instrument Phase 2. BlueSATH, is a €2.7m project (with a contribution by the European Commission of €1.9m) targeting the commercialisation of +10 MW floaters. First phase of the project comprised the deployment of the first prototype using SATH floating technology in the open sea waters of Santander (Spain). The 1:6 scale floater was commissioned in Q2 2020 and tested for a few months.

The purpose of BlueSATH project was dual. On one hand, to de-risk DemoSATH 2 MW demonstrator and on the other hand, to accelerate the industrialization and commercialisation of the +10 MW floaters.

At the end of 2019, DemoSATH project was notified, with a cofinancing national grant to develop the demonstration project with the purpose of validate the technology in real operating conditions, by building a 2 MW prototype and being the first company internationally to have such a prototype, due to the cost involved, but which in turn brings significant competitive advantages for the company and for the area where it will be installed. DemoSATH project will be the fi rst multi-megawatt floating offshore wind turbine connected to the Spanish grid. For the execution of this project, SAITEC has joined forces with one of the major players in offshore wind, RWE Renewables, which will finance part of the project costs and contribute with its extensive experience as the second largest player in offshore wind globally.

Other funded projects that can help to accelerate the market introduction of SATH technology are ArcWind (EAPA_344), MooringSense (851703) and SATHScale (958938) Projects. ArcWind is a European Collaboration project from the European Regional Development Fund (Interreg, Atlantic Area). This project is currently ongoing and consists on the development of SATH- 10MW FOWT adapted to the DTU Reference Wind Turbine. The project includes numerical and experimental validation of the technology. The numerical basis analysis is being validated at CENER (Centro Nacional de Energías Renovables). The experimental analysis is being conducted at LIR-BASIN (UCC-CORK, Ireland).

MooringSense project aims at reducing FOW operational costs through the development of more effi cient strategies and tools for mooring system integrity management. MooringSense will take advantage of mooring systems' updated condition information to reduce OPEX and increase energy production of FOW farms. SATHScale project aims to address the challenge of bringing to market SATH technology through scaling-up the prototype from the technology validated and demonstrated in a relevant environment to Technology Readiness Levels (TRLs) required for commercial products in the relevant markets, i.e., to industrial readiness and maturity for market introduction, exploiting real experiences of the ongoing opensea 2MW demonstrator that will be deployed at BiMEP (Biscay Marine Energy Platform) in Biscay (Spain).

MooringSense project aims at reducing FOW operational costs through the development of more effi cient strategies and tools for mooring system integrity management. MooringSense will take advantage of mooring systems' updated condition information to reduce OPEX and increase energy production of FOW farms. SATHScale project aims to address the challenge of bringing to market SATH technology through scaling-up the prototype from the technology validated and demonstrated in a relevant environment to Technology Readiness Levels (TRLs) required for commercial products in the relevant markets, i.e., to industrial readiness and maturity for market introduction, exploiting real experiences of the ongoing opensea 2MW demonstrator that will be deployed at BiMEP (Biscay Marine Energy Platform) in Biscay (Spain).

Others:

Predicarg project aims to develop, implement, test and validate of a reliable, durable and low-cost mooring system load prediction system through indirect measurements.

LEAF is a R&D project aiming for the optimization of the different Spanish fl oating platforms by developing new tools to allow the optimization of the hydrodynamic behaviour of the platforms, the transport and installation logistics, the control-oriented strategies and the mooring systems.

FLOAT&M project focuses on the development of an "integral solution of O&M for the floating wind industry". Project is based on the contribution of specific research and developments from three ways:

(1) new equipment for O&M, drones, ROVs, connectors.

(2) Digital solutions, twins and models.

(3) new materials and coating.

This will allow the definition of new disruptive O&M strategies specifically adapted to the floating market, an emerging market with a particularly high technological complexity